Excavation Planning

The DTS Project House’s extensive below grade spaces and the properties’ existing physical parameters made planning of the excavations critical. The method for accessing the areas of excavation while also providing protection of existing cactus was determined first and then the order of the excavations were sequenced so as to allow equipment an escape route. The limited site area and steep slope prevented dirt from being easily stockpiled so all excavated material had to either be removed from the site as it was excavated or stockpiled in designated locations out of the way. Accessing the upper areas of the site for excavation necessitated a switchback access ramp, and the desire to protect three existing groves of cactus helped to determine the precise path of the ramp. The ramp also had to provide access for pile drilling rigs and cranes to lift rebar cages into place. Thus, the width and steepness of the ramp determined the size and type of equipment that could access the upper work areas.

Building Design / Construction

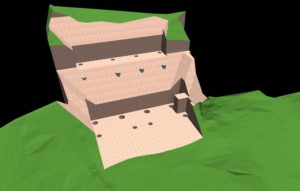

The building design includes a structure with a series of retaining walls that step down the hillside site creating flat building pads at four different elevations. Each of the four elevations requires a cut into the hillside from nine to twenty-two feet high and a 45-degree trim at the top of each excavation above ten feet high. The first several excavations require some amount of earth removal as there is no place on site to stockpile dirt.Each building pad then requires pile excavations, setting of rebar cages, and pouring of concrete piles. Each pad then requires excavation and installation of grade beams and then exposed poured concrete retaining walls siting on top of the grade beams. The retaining walls then require waterproofing, drainage piping in gravel, and compacted backfill. The sequence and extent of each excavation must allow for materials, equipment, and workers to safely get to the proper locations to complete each of these operations on all four excavated levels.

Steep Slope / Limited Access

The steep slope, along with the limited access, of the combined three lots makes it necessary to plan the sequencing of the extensive excavations and coordinate the excavations with the concrete pour sequencing. It is critical to make sure that equipment required for both excavation and concrete installation could get to the necessary locations, could get back off site, and could then get to the remaining excavation and concrete pour locations. Each excavation sequence has to be limited so that neither the removal or stockpiling of dirt prevents future required equipment movements and access.It had to be determined which stages of excavation and concrete operations would originate from Creston Drive at the top of the site and which would be conducted from Hargrave Drive at the bottom of the slope. It was determined that all excavation equipment and dirt removal would have to originate from below from Hargrave Drive or equipment would become trapped with no way to get off site. The limited width and numerous curves in Hargrave Drive (Creston Drive has the same limitations) determined the size and type of equipment that could safely access the site.

Limited Flat Storage / Working Space

The steep hillside site contains very little sufficiently flat area to store or stockpile dirt or store materials for the concrete installations. The excavations themselves also traverse from one side of the site to the other leaving very little area outside of the area of excavation. Excess dirt must be removed as the excavations progress and there must be a means to get the wood formwork, rebar, and equipment from Hargrave up to the necessary locations as they are needed as they cannot be stored on site.Thus, an access ramp or ramps up and down the hillside must be constructed from Hargrave Drive to the level of each excavation. Each excavated flat area must be large enough to set-up cranes, lay out rebar cages and provide space to maneuver and set rebar cages in pile excavations.

Access Ramp

Based upon the decision that all excavation equipment would be brought up from the bottom to the necessary locations, a ramp was devised with the proper incline to get the excavation equipment, drilling rigs, and cranes up the hill and back down the hill. The steep angle of the ramp makes it necessary to only use equipment with tracks. The switchback ramp was laid out to weave around the existing cactus patches to be preserved. The ramp had to also allow workers to safely walk up and down. The dirt surface of the ramp is constantly loosened up so the tracks on the equipment can gain traction as the equipment going up and down compacts the dirt into a dangerously slick surface.The placement of the ramp also had to allow for rebar cages to either be brought up on equipment or dragged up without hitting the existing cactus. The limitation of how long a rebar cage could be brought up the ramp determined if the cages were fabricated as a single piece or would have to be spliced together in the hole. The ramp from Hargrave Drive to the highest area of excavation was the first excavation with a combination of cut and fill to get the proper consistent incline.

Protection of Existing Cactus

The excavation planning begins with the absolute necessity to protect the three existing areas of cactus. Protection of the cactus is a philosophical decision to connect the historical, existing, and altered site, and is critical to meet specific sustainability requirements. The location of the existing cactus helps determine how the access ramp lays out and switches back and forth between the existing cactus patches. Five to six foot barriers are constructed around the existing cactus areas to prevent piled up ramp dirt and other debris from intruding and damaging the cactus.

Recycling Excavated Material

Excavated earth material that comes out of the ground as rock is to be saved for filling the gabion walls of stone. An area for storage at bottom of hill was designated and rocks were purposely rolled down hill to assure they were indeed rock and not just hard dirt. The excavated rock was intentionally arranged to be rained on and weathered to confirm they will hold up to weathering once placed in the gabion cages. The rock is eventually laid flat to determine the quantity of gabion cages that the rock will filled.