Every building is a prototype. No two are alike. ~ Helmut Jahn

CONCRETE PLANNING

Detailed planning of the concrete pour sequencing is critical both because of the restrictive site parameters affecting concrete pours and because much of the concrete is exposed in the finished building. The logistics and protocols for how the pours are made will directly affect the qualities of the exposed concrete. The desire to control the outcome of the exposed concrete also necessitates the planning of the formwork construction and the reinforcing steel installation.

Logistics / Protocols

The existing neighborhood and site conditions greatly affected the planning of concrete pours. The limitations of accessing the site through the windy and often blocked streets of the neighborhood not only affects the logistics of concrete pours but was also one among several considerations for the decision to do a board form concrete finish and not a smooth finish.The uncontrollable conditions of Los Angeles traffic, unknown ability to get trucks through the neighborhood to the construction site, and little ability to stage multiple trucks at the site (one truck has to leave and pass the next truck staged approximately a quarter mile down the hill) made it necessary to assume there would be interruptions in the concrete trucks arriving on site. A precise concrete finish is not possible when a precise process is not available.

The decision was made early on to pump concrete from Creston Drive above the site and not from below on Hargrave Drive. Working with gravity more than made up for the fact that hose lengths for some pours were made longer. The street layout and dimensions of the intersection of Creston and Durand provided sufficient room to set up the pumper, including a boom pump when necessary, and the concrete truck so that we did not have to close the street for concrete pours. Since the Owner building the DTS Project House owns the property adjacent to the Creston Durand intersection, we have the ability to park equipment in front of the property blocking driveways and entrances. The cul-de-sac at end of Durand provided a close by place for trucks to turn around without backing.

Traffic control was critically important to successfully making pours without negatively disrupting the neighborhood. Care was taken to only pour on certain days, such as not on Friday trash days when trash cans are on the curbs and trash trucks are on the street. Pours were not made first thing in the morning when residents are leaving for work and school and the traffic on freeways between the concrete plant and site is the heaviest. Because of the steep hillside streets, trucks made to carry 10cy of concrete can only safely carry 8cy to avoid any spillage in transport.

A sample exposed wall was poured as part of one of the pour sequences to test the visual outcomes of a concrete mix substituting fly ash for 20% of the Portland cement and options for sandblasted wood formwork. The sample wall was constructed near the bottom of site to test the ability to effectively deliver concrete to furthest point of the construction. A boom pump is used for all pours with a concrete fall of more than ten feet as it is impossible to effectively maneuver the long, heavy hoses manually in and out of deep formworks densely filled with steel reinforcing.

A series of temporary stairs are constructed to get to and from the various levels of the site excavations including a stair on the Owner’s adjacent property. Scaffolding and other means are constructed to get workers to the necessary precise locations and heights for wall pours to both place and maneuver the hoses into proper position, properly vibrate the concrete, and finish the concrete at top of wall pours.

Sequencing

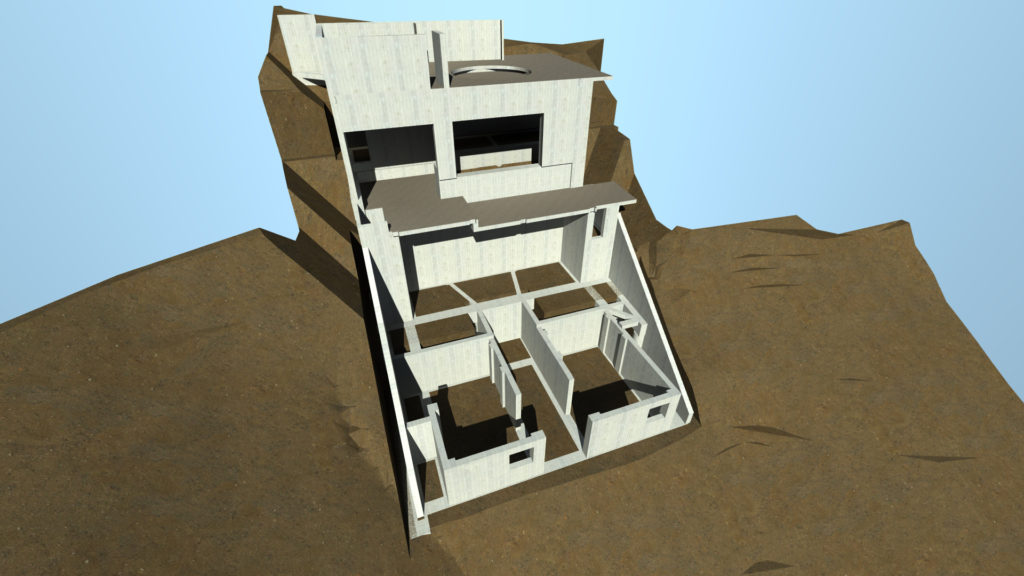

Concrete pours include piles and grade beams buried in the earth, retaining walls with covered and exposed surfaces, freestanding walls with covered and exposed surfaces, slabs on grade, and exposed slabs above grade. Determining the scope of each pour and the sequence of the various pours starts with coordinating with the excavation sequence so that the excavations allow the necessary work to install the concrete and then the placement of concrete does not prevent subsequent excavations.

The sequencing and scope must consider the neighborhood and site conditions affecting the logistics of concrete installation. There are limits to the amount of concrete that can be delivered and finished for a single continuous pour. The scope and sequencing of each pour also has to account for and coordinate with other construction operations such as installation of structural steel and wood framing. Most critically, the sequencing must lead to the intended outcome for the exposed concrete.

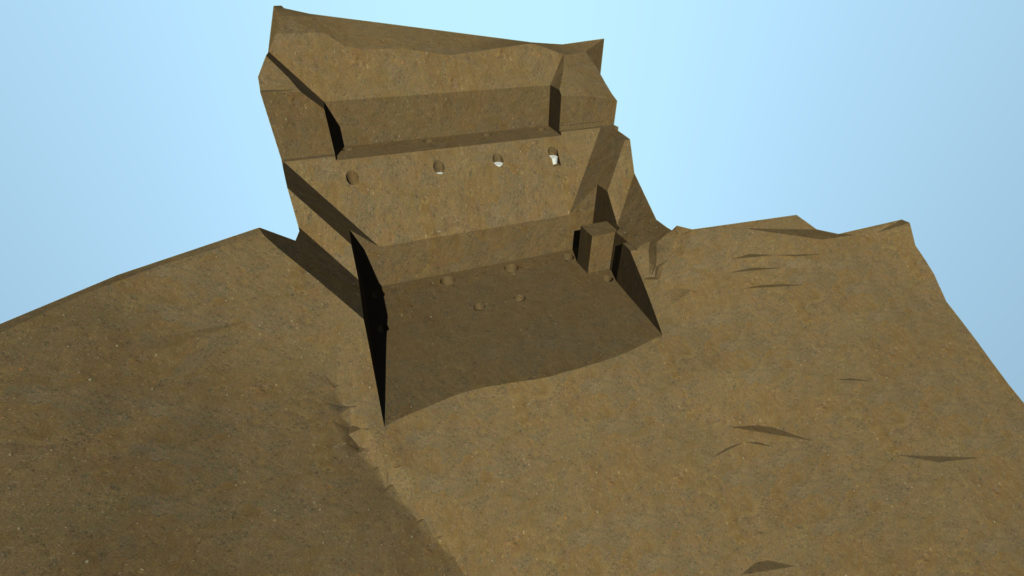

Accounting for all of the aspects affecting the concrete pours, the sequencing was divided into 28 separate concrete pours including four pours of piles, eight pours of grade beams, twelve pours of walls, and four pours of slabs. In order to work out the sequencing and properly coordinate it with the excavations and other building construction operations the sequencing is modeled in a 3D digital model and each sequence is documented with a 3D drawing. Determining the sequencing was necessary in order to design and document the formwork construction and layout the rebar installation.

In order to achieve the joint patterns and layout of exposed ties on the exposed concrete walls, formwork is designed and documented to the same extent as the portions of the building that are constructed and remain in the finished building. Although the formwork may not remain its design and construction mark the exposed concrete forever. The formwork is also designed in order to implement the necessary sequencing of the concrete pours.

Reinforcing Steel

In order to place concrete ties where desired the reinforcing steel must be placed in specific locations. In order to install the rebar as required and to most efficiently install the rebar without waste, the reinforcing steel fabrication and placement was fully “designed” and documented.